Float scaffolds are supported by a system of components that work together to create a stable and safe work platform. Uprights provide vertical support, while base plates transfer weight to the ground. Cross braces enhance stability, and ledgers support the platform. The platform itself serves as the work surface, and guardrails and toeboards prevent falls and object displacement, respectively. The integrated system of these components ensures the float scaffold can withstand the weight of workers and materials, providing a secure and efficient work environment.

Components of a Float Scaffolding System

Imagine you’re a construction worker, high up on a scaffold, hammering away at a building. Safety is paramount. That’s why it’s crucial to understand the components of a float scaffolding system, which provides a stable and secure work platform.

Uprights: Vertical Support

- Uprights are the backbone of a float scaffold, providing vertical support that determines the height of the structure. These sturdy posts are usually made of steel or aluminum.

Base Plates: Stable Foundation

- Base plates are the unsung heroes that anchor the scaffold to the ground. They distribute the weight of the scaffold and prevent it from sinking into the surface.

Cross Braces: Stability Enhancers

- Cross braces are like the muscles of a scaffold, connecting uprights and preventing swaying or buckling. They strengthen the structure and ensure stability.

Ledgers: Platform Supports

- Ledgers are the horizontal beams that support the platform. They distribute the weight of workers and materials across the uprights.

Platform: The Work Surface

- The platform is the heart of the scaffold, providing a stable and spacious work surface for crew and equipment.

Uprights and Vertical Support

- Explain the role of uprights in providing vertical support and defining the height of the scaffold.

Uprights: The Backbone of a Float Scaffold System

In the realm of scaffolding, uprights stand tall as the unsung heroes, providing the essential vertical support and defining the lofty heights of these temporary structures. These robust members serve as the backbone of a float scaffold system, ensuring the stability and safety of workers and materials alike.

As the name suggests, uprights are vertical components that rise from the ground, interlocking with other components to form a sturdy framework. They are typically made of lightweight but durable materials such as aluminum or steel, allowing for easy transportation and assembly while providing ample strength.

The height of the scaffold is determined by the length of the uprights used. Taller uprights enable workers to reach higher elevations, providing access to hard-to-reach areas. However, it’s crucial to maintain a proper height-to-base ratio to ensure stability and prevent tipping.

Base Plates: The Foundation of Sturdy Scaffolding

In the realm of float scaffolding, every component plays a crucial role in ensuring stability and safety. **Base plates**, as the unsung heroes of this architectural ensemble, bear the colossal responsibility of transferring the scaffold’s weight to the ground, preventing it from sinking into the depths of yielding surfaces.

These sturdy platforms, often rectangular or square in shape, are engineered to withstand the immense load of the scaffold, its occupants, and the myriad tools and materials they carry. Their wide surface area distributes the weight evenly, minimizing pressure on the ground and preventing unsightly divots or dangerous subsidence.

Moreover, base plates act as a protective barrier between the scaffold’s uprights and the ground, shielding them from moisture and other environmental elements that could compromise their integrity. By keeping the uprights elevated, they also prevent water from seeping into the scaffold’s joints, which could lead to corrosion and structural weakness.

In essence, **base plates** are the cornerstone of a stable and dependable scaffolding system. Without their unwavering support, the entire structure would be vulnerable to collapse, posing a grave danger to workers and passersby alike.

Cross Braces: The Unsung Heroes of Scaffolding Stability

Imagine a scaffolding without cross braces. It would be a wobbly, unstable structure, prone to swaying and buckling under even the slightest weight. Cross braces are the unsung heroes of a float scaffolding system, providing the much-needed structural integrity to keep workers safe and secure.

Their purpose is simple yet critical: to connect uprights, the vertical support beams, and prevent them from bending or collapsing inward. Without cross braces, the uprights would only be able to support a limited amount of weight before succumbing to the forces of gravity.

Cross braces are typically made of sturdy metal and come in various shapes and sizes. They are strategically placed diagonally between uprights, forming an intricate network of support. This crisscrossing pattern creates a rigid frame that effectively distributes the weight of the scaffold and workers across the entire structure.

The result is a scaffold that is remarkably stable and resistant to swaying or buckling. Cross braces work tirelessly behind the scenes, ensuring that the platform remains level and secure, allowing workers to focus on their tasks without worrying about their safety.

Without these sturdy braces, a float scaffolding system would be nothing more than a precarious collection of metal poles. It is only through the combined strength of uprights and cross braces that a scaffold transforms into a safe and reliable work platform, enabling workers to reach new heights with confidence.

Ledgers: The Platform’s Unsung Heroes

In the world of float scaffolding, where safety and efficiency reign supreme, there’s an often overlooked workhorse that plays a pivotal role in ensuring a stable and secure work surface for construction professionals: the ledgers.

Imagine the platform as the stage where our scaffolding story unfolds. However, without sturdy pillars of support, this platform would be nothing but a shaky, unreliable structure. Enter the ledgers, the unsung heroes that connect the uprights (vertical supports) and distribute the weight of the platform and its occupants across them.

Think of ledgers as the scaffolding’s backbone. They run horizontally along the uprights, acting as beams that transfer the platform’s load to the uprights. This distribution of weight ensures that the scaffolding remains stable even under demanding conditions.

By connecting the uprights, ledgers also prevent swaying and buckling of the scaffold. Just as a bridge is supported by multiple piers, ledgers provide additional points of support for the platform, ensuring that it doesn’t sag or collapse.

Without ledgers, the platform would be unstable and vulnerable to collapse, putting workers at risk. Therefore, it’s essential to ensure that ledgers are properly installed and secured, creating a solid foundation for a safe and productive work environment on the float scaffolding.

The Platform: A Vital Element for Safe and Efficient Work

As we delve into the intricate details of float scaffolding systems, we arrive at the heart of it all – the platform. This paramount component serves as the foundation for all work performed, providing a secure and stable surface for both workers and materials.

The platform is meticulously constructed using durable materials, engineered to withstand the demanding conditions of various work environments. Each platform is meticulously tested to ensure it meets the highest standards of safety and stability, enabling workers to perform their tasks with confidence and peace of mind.

Beyond its primary function as a work surface, the platform also plays a crucial role in distributing weight evenly across the uprights, ensuring the scaffold remains well-balanced and устойчивый. This integral aspect of the float scaffolding system contributes significantly to its overall safety and reliability.

In essence, the platform is not merely a component but the very **core of the float scaffolding system, upon which the success and safety of any project depend.**

Guardrails: The Lifeline of Float Scaffolds

When working at elevated heights, the risk of falling is ever-present. That’s where guardrails come into play, serving as indispensable safety barriers on float scaffolds. They act as a crucial line of defense, preventing workers from stepping off the platform and plummeting to the ground.

Guardrails are typically constructed from sturdy metal or wood, forming a protective perimeter around the work surface. They are designed to be strong enough to withstand accidental impacts or pushes, ensuring that workers remain secure on the scaffold. Their presence provides peace of mind, allowing workers to focus on their tasks without the constant fear of falling.

The height of guardrails is carefully regulated, typically ranging from 39 to 45 inches off the platform. This height provides a balance between accessibility and protection, allowing workers to easily step onto the platform while minimizing the risk of tripping or falling over the railing.

Guardrails also play a vital role in preventing objects from falling off the platform. This is especially important when working with tools, equipment, or materials that could pose a hazard to those below. By containing these items within the work area, guardrails help create a safer environment for everyone involved.

In summary, guardrails are an essential component of float scaffolding systems, ensuring the safety and well-being of workers. Their sturdy construction and strategic placement provide a secure and protected work environment, allowing workers to perform their tasks with confidence and peace of mind.

Toeboards: Preventing Objects from Falling and Ensuring Safety on Float Scaffolds

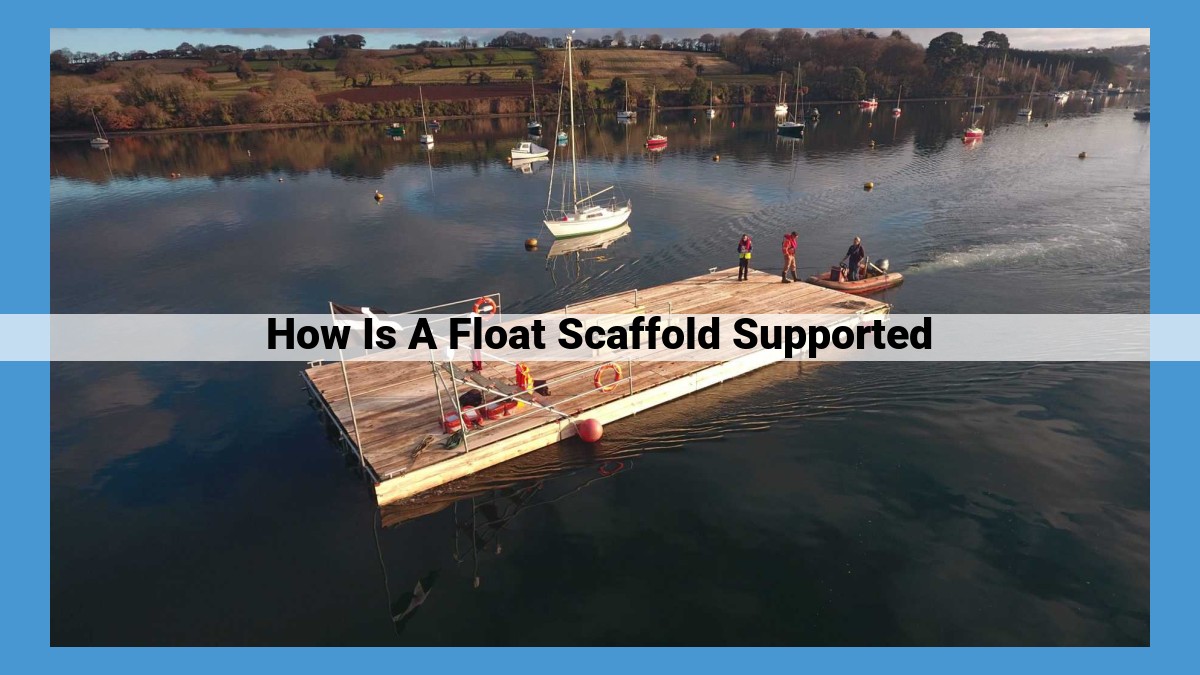

Float scaffolds play a crucial role in various construction and maintenance tasks, providing a stable and secure work platform for workers. Among the essential components of a float scaffold system are toeboards, which serve a vital purpose in maintaining job site safety.

Purpose of Toeboards

Toeboards are low-profile barriers installed along the open edges of a scaffold platform. Their primary function is to prevent objects from accidentally falling off the platform and causing injuries to individuals working below. These objects could range from tools, materials, and debris to personal belongings.

How Toeboards Work

Toeboards typically consist of solid panels or mesh screens that are attached to the bottom of the scaffold platform. They create a physical barrier that intercepts falling objects and prevents them from dropping to the ground. This is especially important when workers are performing tasks that involve handling heavy equipment or materials on the scaffold.

Ensuring Worker Safety

The presence of toeboards on a float scaffold ensures the safety of workers in several ways:

- It reduces the risk of objects falling off the platform and striking individuals below.

- It prevents tripping hazards caused by protruding objects on the platform edge.

- It promotes a clean and organized work environment by containing materials and debris on the platform.

Compliance and Best Practices

To ensure maximum safety, it is crucial to follow the relevant regulations and best practices for installing and maintaining toeboards. These guidelines typically specify the minimum height, material, and strength requirements for toeboards. Regular inspections are also essential to verify their integrity and prevent any potential hazards.

Toeboards are an often overlooked but critical component of float scaffolds. Their seemingly simple design plays a significant role in ensuring the safety of workers by preventing objects from falling off the platform. By incorporating toeboards into the scaffold design and adhering to proper maintenance practices, construction professionals can create a secure and productive work environment that minimizes the risk of accidents.

The Interconnected Symphony of a Float Scaffolding System

When it comes to accessing elevated work areas, float scaffolding reigns supreme, providing a reliable and versatile solution for countless industries. Its stability and safety are not coincidences but the result of an intricate symphony played by its various components.

Uprights, the backbone of the scaffold, define its height and provide vertical support. They’re like the pillars of a building, ensuring the scaffold can withstand the weight of workers and materials.

Base plates, the anchor points, connect the uprights to the ground, transferring the load and preventing the scaffold from sinking into soft soil. They act as the foundation, ensuring the scaffold remains firmly rooted.

Cross braces, the stabilizers, connect the uprights like a crisscrossed latticework, preventing them from swaying or buckling under pressure. They’re the unsung heroes, providing strength and rigidity to the scaffold.

Ledgers, the platform supporters, are the horizontal beams that support the platform, distributing the load across the uprights. They’re the bridge between the uprights and the platform, ensuring a stable work surface.

Platform, the worker’s domain, is the stable and spacious surface where workers can perform their tasks. It’s the focal point of the scaffold, providing a secure base for operations.

Guardrails, the safety guardians, surround the platform, preventing workers from stepping off and falling to the ground below. They’re the watchful protectors, keeping workers safe from potential hazards.

Toeboards, the object retainers, line the edge of the platform, preventing objects like tools or materials from falling and injuring people below. They’re the unsung heroes, protecting workers from unseen dangers.

Each component, like a musical note, plays a vital role in the overall harmony of the scaffold. When assembled and interconnected properly, they create a stable and safe scaffolding system that empowers workers to perform their duties with confidence. It is a testament to the ingenuity of human engineering, where every piece contributes to the greater good, ensuring the well-being of those who rely on it.