A binding constraint is a resource or factor in a production process that limits output, preventing a system from reaching its maximum capacity. Binding constraints are characterized by their impact on output, meaning that any increase in the constrained resource will result in an increase in output. Identifying and addressing binding constraints is crucial for optimizing production and resource allocation. Strategies for relaxing binding constraints include increasing capacity, improving efficiency, or introducing technology, leading to increased output and efficiency. Goal programming and linear programming are mathematical techniques used to address problems with multiple binding constraints, allowing organizations to optimize resource utilization and achieve desired outcomes effectively.

In the realm of resource allocation and production optimization, maximizing output is paramount. This can only be achieved by understanding and effectively managing the concept of binding constraints. They are the key roadblocks that hinder your ability to reach your full potential, acting like invisible barriers that limit your progress.

Binding constraints are those resource limitations that prevent you from using other resources more effectively. Their presence means that no matter how much you try to increase production by investing in other areas, the bottleneck caused by the constraint will always hold you back. Identifying and addressing binding constraints is the cornerstone of unlocking your organization’s true potential.

Understanding Binding Constraints

In the realm of production and resource allocation, constraints play a pivotal role in determining the limits of our output. Constraints can be likened to invisible boundaries that restrict us from achieving our full potential. Among these constraints, binding constraints stand out as the most formidable, setting an unyielding limit on our capacity to produce.

Binding constraints are those that operate at their maximum capacity. They are the weak links in the chain of production, acting as bottlenecks that hinder the smooth flow of resources. Unlike non-binding constraints, which have some flexibility and can be relaxed or expanded without significantly impacting output, binding constraints are inflexible and unyielding.

Identifying binding constraints is crucial for unlocking the full potential of production processes. To discern a binding constraint from its non-binding counterpart, we must examine the impact it has on output. If a constraint limits output, regardless of the abundance of other resources, then it is a binding constraint.

Characteristics of Binding Constraints:

- Fixed and Inflexible: Binding constraints cannot be easily relaxed or expanded. They represent physical limitations or resource scarcity that cannot be readily overcome.

- Limiting Factor: Binding constraints are the primary determinant of output capacity. They effectively set the upper limit for production.

- Interdependent: Binding constraints often interact with other constraints, creating a complex network of interdependencies. Relaxing one binding constraint may inadvertently create another.

- Hidden Constraints: Binding constraints may not always be apparent. They can be subtle or masked by other factors, making their identification challenging.

Identifying Binding Constraints in Production Processes

Understanding binding constraints is crucial for unlocking maximum output. These constraints can severely limit production by acting as bottlenecks in the process. To effectively manage these limitations, we must first identify them.

Observing Production Flow: By meticulously examining each step of the production process, potential binding constraints can be identified. Observe where bottlenecks occur – stages where work accumulates or delays are frequent. These bottlenecks often indicate the presence of binding constraints.

Analyzing Resource Utilization: Evaluate the utilization of key resources, such as raw materials, machinery, and labor, to uncover potential binding constraints. If a specific resource consistently operates at or near its full capacity, while other resources remain underutilized, it may signal a binding constraint.

Monitoring Output Levels: Track production output over time to spot constraints that may not be immediately apparent. If output remains stagnant or fails to meet expectations despite increased effort, it’s an indication that a binding constraint may be present.

Impact Analysis: Once binding constraints are identified, their impact on production output must be carefully analyzed. Determine how much output is being lost due to the constraint and assess its potential effect on overall business performance. This analysis will help prioritize which constraints to address first.

Relaxing Binding Constraints: Unlocking the Potential for Increased Output and Efficiency

In the realm of production and resource allocation, binding constraints pose a significant challenge to maximizing output. These constraints act as roadblocks, preventing processes from operating at their full capacity. Understanding how to relax or remove binding constraints is crucial for unlocking the true potential of any organization.

Strategies for Relaxing Binding Constraints

Several strategies can be employed to mitigate the impact of binding constraints. One effective approach is to increase the capacity of the constrained resource. This can be achieved by expanding the physical facilities, hiring additional staff, or acquiring new equipment. Alternatively, organizations can reduce the demand for the constrained resource. This may involve eliminating unnecessary processes, outsourcing certain tasks, or finding innovative ways to reduce consumption.

Benefits of Relaxing Binding Constraints

Relaxing binding constraints offers a multitude of benefits that can significantly enhance organizational performance:

-

Increased output: By removing the bottlenecks caused by binding constraints, organizations can significantly increase their production capacity. This leads to higher sales, revenue, and profitability.

-

Improved efficiency: With binding constraints relaxed, processes can flow more smoothly, reducing waste and minimizing downtime. This results in increased productivity and lower operating costs.

-

Enhanced customer satisfaction: By meeting demand faster and more reliably, organizations can improve customer satisfaction levels. This leads to increased loyalty, repeat business, and positive word-of-mouth.

Case Study: Unlocking Hidden Capacity

Consider the example of a car manufacturing plant facing binding constraints in its assembly line. By analyzing the production process, it was discovered that the painting booth was the bottleneck, limiting the plant’s overall output. To relax this constraint, the plant invested in a new, high-speed painting line. This investment significantly increased the output capacity, allowing the plant to meet growing demand and secure a competitive edge in the market.

Understanding and managing binding constraints is paramount for optimizing production and resource allocation. By exploring strategies to relax these constraints, organizations can unlock their true potential, driving increased output, efficiency, and ultimately, success. Remember, the key to maximizing performance lies in identifying and eliminating the barriers that hold you back.

Goal Programming and Linear Programming in Binding Constraint Management

When optimizing production processes, understanding the concept of binding constraints is paramount. These limitations restrict output, and addressing them is essential for maximizing efficiency. Goal programming and linear programming serve as powerful tools in managing binding constraints.

Goal programming tackles problems with multiple binding constraints. Its objective is to find the best solution that minimizes deviations from predetermined goals. These goals, such as maximizing output or minimizing costs, are prioritized. The program allocates resources to meet these goals while considering the binding constraints.

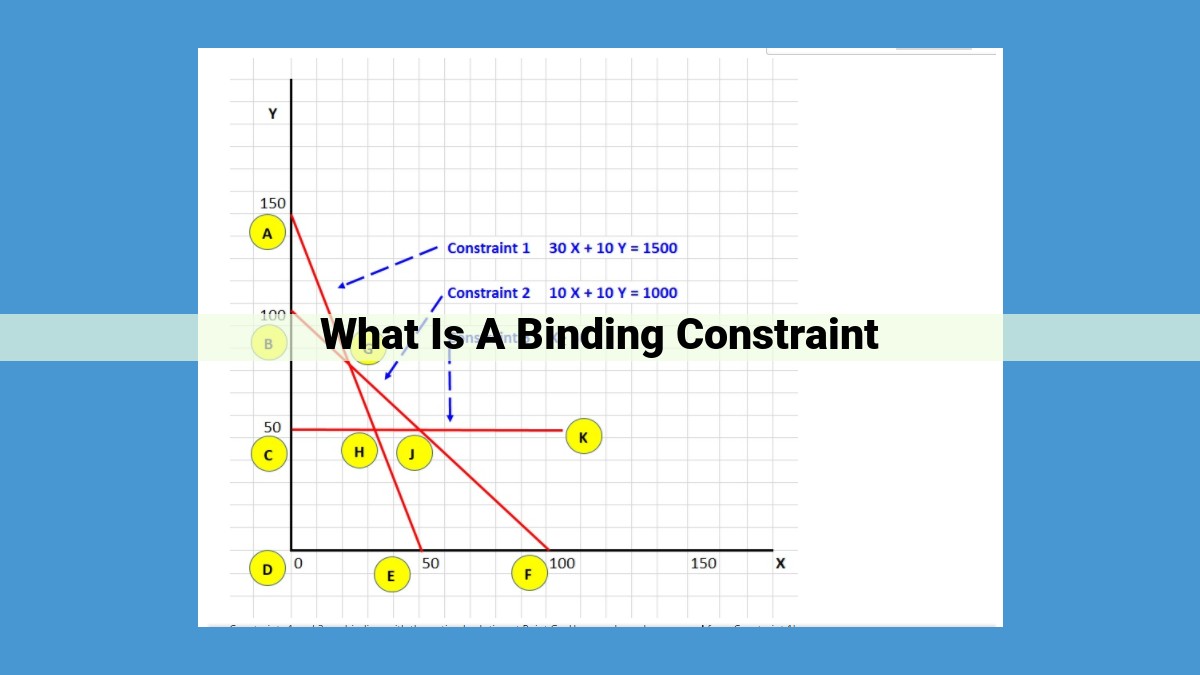

Linear programming (LP) is a technique used to solve goal programming problems. LP models represent the production process as mathematical equations and constraints. By optimizing this model, decision-makers can determine the optimal production plan that maximizes output while adhering to the binding constraints.

LP provides several advantages in binding constraint management:

- It allows for multiple objectives to be considered simultaneously, enabling the optimization of both production and resource allocation.

- LP can handle complex constraints, including non-linear and integer constraints.

- The results of LP can be used to identify bottlenecks and analyze the impact of different constraints on output.

By utilizing goal programming and LP, organizations can effectively manage binding constraints, leading to increased productivity, reduced costs, and optimized resource utilization.

Remember, understanding and managing binding constraints is crucial for businesses seeking to achieve maximum output and efficiency in their production processes.