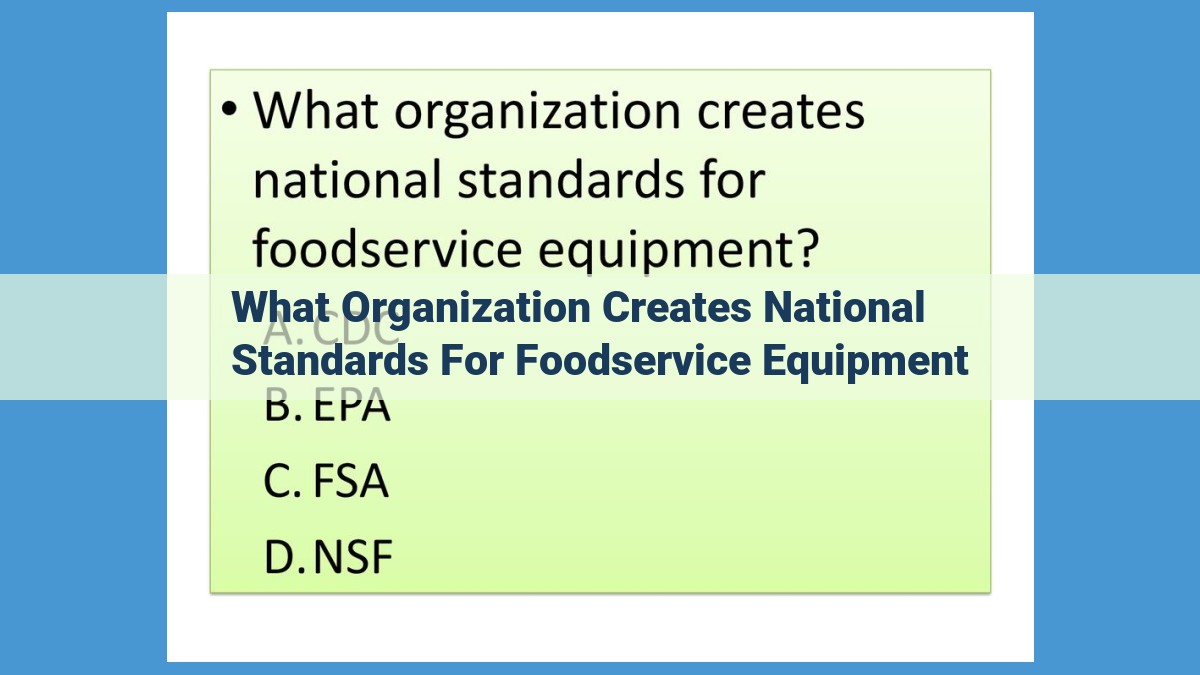

National standards for foodservice equipment are set by various organizations to ensure quality and safety. The American National Standards Institute (ANSI) coordinates and approves standards through collaboration with industry experts, while the National Sanitation Foundation (NSF) develops standards and offers certification programs specific to public health protection. Underwriters Laboratories (UL) focuses on electrical, fire, and cybersecurity safety, offering rigorous testing and certification programs. The International Organization for Standardization (ISO) provides international standards for quality, environmental management, and information security in the foodservice industry. Compliance with these standards is crucial for ensuring safe and efficient foodservice equipment.

National Standards for Foodservice Equipment: Ensuring Quality and Safety

In the bustling world of foodservice, maintaining the integrity and safety of food is paramount. National standards for foodservice equipment play a crucial role in ensuring that food is prepared and served in a way that minimizes risks and protects consumers. These standards provide a framework for designing, manufacturing, and operating foodservice equipment, ensuring its compliance with stringent health and safety regulations.

Standardization is essential for achieving uniformity and consistency in the foodservice industry. It helps to establish baseline requirements for equipment, ensuring that it operates efficiently and safely, regardless of the manufacturer or model. By adhering to national standards, foodservice establishments can demonstrate their commitment to quality, safety, and consumer well-being.

ANSI: The American National Standards Institute

The seamless operation of our everyday lives is largely due to the standardization of products, processes, and services. In the world of foodservice equipment, the American National Standards Institute (ANSI) plays a pivotal role in setting and approving national standards.

Established in 1918, ANSI is a private, non-profit organization that brings together representatives from industry, government, academia, and consumer groups to develop and approve national standards. These standards are voluntary, but they carry significant weight in the marketplace and are often used as the basis for laws and regulations at the federal, state, and local levels.

ANSI’s standards development process is rigorous and transparent. It involves a consensus-based approach, where all stakeholders have an opportunity to provide input and contribute to the development of the final standard.

Once developed, ANSI standards are published and made available to the public. They are then reviewed periodically and updated to reflect changes in technology and best practices.

In addition to developing standards, ANSI also offers accreditation programs to organizations that conform to its standards. This accreditation demonstrates that an organization has the competence and expertise to perform a specific activity, such as testing and certifying foodservice equipment.

By working with industry experts and offering accreditation programs, ANSI ensures that national standards for foodservice equipment are relevant, up-to-date, and based on the latest science and technology. This helps to improve the quality and safety of foodservice equipment, and it also makes it easier for businesses to comply with regulatory requirements.

NSF: The National Sanitation Foundation

In the realm of public health and safety, the National Sanitation Foundation (NSF) stands as a beacon of excellence. Founded in 1944, NSF’s mission is to safeguard consumers from harmful contaminants and ensure the safety of public health systems.

Setting the Standards for Foodservice Equipment

NSF’s impact extends far beyond the healthcare industry, reaching into the very heart of our kitchens and dining establishments. As a leading developer of national standards for foodservice equipment, NSF plays a pivotal role in ensuring that the equipment we rely on to prepare and serve our food is safe and sanitary.

Through rigorous research and testing, NSF experts establish comprehensive standards that address every aspect of foodservice equipment performance, from material safety to cleaning and maintenance. These standards are based on the latest scientific findings and industry best practices, ensuring that equipment meets the highest standards of hygiene and safety.

Certification Programs for Foodservice Equipment

To help manufacturers demonstrate their commitment to quality and safety, NSF offers a comprehensive suite of certification programs for foodservice equipment. These programs provide independent verification that equipment meets NSF’s stringent standards.

The NSF certification mark is a trusted symbol of excellence, recognized by industry professionals and consumers alike as a guarantee of safety and reliability. By choosing foodservice equipment that bears the NSF certification mark, operators can rest assured that they are investing in equipment that meets the highest standards of hygiene and performance.

UL: Enriching Foodservice Safety with Uncompromising Standards

UL, a global leader in safety science, plays a pivotal role in ensuring the safety and reliability of foodservice equipment. Its unwavering focus on safeguarding the public against electrical hazards, fires, and cybersecurity threats has made it a trusted partner in the foodservice industry.

UL’s meticulous standards are rooted in rigorous testing and certification programs. Each piece of foodservice equipment undergoes a battery of tests designed to evaluate its performance under a wide range of operating conditions. This ensures that the equipment meets UL’s stringent requirements for electrical safety, fire safety, and cybersecurity.

When foodservice equipment bears the prestigious UL Mark, it signifies that it has met the highest levels of safety and quality. This mark is a testament to the equipment’s ability to protect users from electrical shocks, fires, and data breaches, providing peace of mind and reducing risk in the fast-paced and demanding foodservice environment.

UL’s unwavering commitment to innovation and excellence has earned it a reputation as a trusted authority in the industry. Its standards are continuously updated to keep pace with the latest technological advancements and address evolving safety concerns. By partnering with UL, foodservice equipment manufacturers can demonstrate their commitment to safety and protect their customers’ well-being.

With UL’s rigorous testing and certification programs, foodservice businesses can operate with confidence, knowing that their equipment meets the highest safety standards. UL’s unwavering dedication to protecting the public and ensuring the reliability of foodservice equipment makes it an indispensable partner in the pursuit of safe and efficient foodservice operations.

ISO: Setting Global Benchmarks for Foodservice Equipment Quality

Standardized benchmarks play a crucial role in ensuring the safety and quality of products and services worldwide. In the realm of foodservice equipment, the International Organization for Standardization (ISO) stands as a pillar of excellence. This esteemed organization develops and publishes international standards in a myriad of fields, including the foodservice industry.

ISO’s Role in International Standardization:

ISO is a non-governmental organization with an esteemed reputation for providing guidance and expertise in the development of technical standards. Its members are composed of representatives from government agencies, industry associations, and experts from around the globe. Through their collaborative efforts, ISO seeks to harmonize global practices and establish a common language for quality and safety.

Relevance for Foodservice Equipment:

As a global player in the foodservice equipment industry, ISO’s standards encompass a wide range of aspects, including:

- Quality Management: ISO 9001 is the cornerstone of quality management systems and provides a framework for organizations to improve their processes and operations.

- Environmental Management: ISO 14001 establishes guidelines for organizations to minimize their environmental impact and promote sustainable practices.

- Information Security: ISO 27001 outlines best practices for protecting sensitive information and mitigating cybersecurity risks.

Benefits of Compliance:

Compliance with ISO standards offers a multitude of benefits for manufacturers and end-users alike:

- Enhanced Safety: ISO standards prioritize the safety of foodservice equipment, ensuring that it meets stringent safety requirements to protect consumers.

- Increased Efficiency: By standardizing processes and specifications, ISO standards streamline production and maintenance, resulting in greater efficiency and cost savings.

- Global Recognition: ISO standards are recognized and respected worldwide, providing manufacturers with a competitive advantage and facilitating international trade.