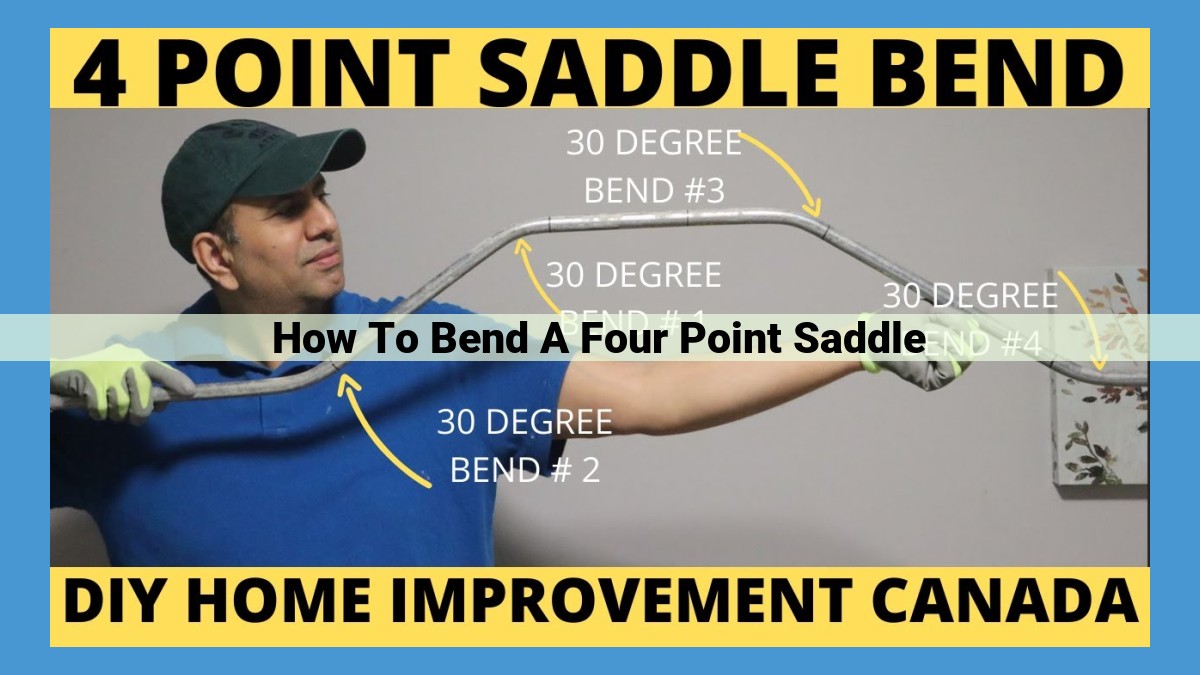

To bend a four-point saddle, secure it to a jig, apply heat to soften the material, and gradually bend it using bending pliers or a jig. Choose the bend radius, angle, and location based on the saddle’s shape and your body type. Use the correct tools and techniques to heat, bend, cool, anneal, and shape the saddle. Check and adjust the bend using a gauge and angle meter, and polish the saddle for a comfortable finish.

Understanding Saddle Geometry: A Comprehensive Guide to Choosing the Perfect Saddle

When it comes to cycling, choosing the right saddle is crucial for comfort, performance, and overall enjoyment. Understanding saddle geometry is essential for selecting a saddle that perfectly complements your riding style and body type.

Saddle Shapes, Widths, and Angles

Saddles come in a wide variety of shapes, widths, and angles to cater to different riders’ needs.

- Shape: Flat, curved, or cutout saddles provide varying levels of support and pressure distribution.

- Width: Wider saddles offer more stability and support for wider sit bones, while narrower saddles are ideal for smaller riders or those who prefer a more aerodynamic position.

- Angle: Nose-down saddles facilitate aggressive forward positioning, while nose-up saddles promote a more upright posture.

Identifying the Four Points of the Saddle

A saddle consists of four key points:

- Nose: The front of the saddle, designed to prevent your legs from rubbing against the front wheel.

- Seat: The main sitting area, providing support and comfort for your sit bones.

- Rails: The metal bars that attach the saddle to the bike’s seatpost.

- Cantle: The rear part of the saddle, offering additional support and determining the rider’s position.

Planning the Bend

To ensure a comfortable and efficient ride, it’s essential to determine the correct bend for your saddle. Consider the following factors:

- Radius of curvature: Determines how much the saddle curves and affects overall support and pressure distribution.

- Angle of bend: Indicates the saddle’s tilt, allowing you to fine-tune your riding position.

- Location of the bend: Refers to the point along the saddle rails where the bend occurs, influencing your leg extension and comfort.

Understanding the Essential Components of a Saddle

Identifying the different parts of a saddle is crucial for understanding its function and selecting the right one for your riding needs. Let’s dive into the anatomy of a saddle and explore its four key components:

-

The Nose: Positioned at the front of the saddle, the nose provides support and control during climbing or standing while pedaling. Its shape influences the rider’s position on the saddle and affects the distribution of weight on the hands.

-

The Seat: The central and largest part of the saddle, the seat supports the rider’s weight and provides comfort during prolonged rides. Its width and shape should complement the rider’s sit bones and prevent pressure points.

-

The Rails: The rails are metal bars that run along the length of the saddle and attach it to the seat post. They come in varying diameters and materials, affecting the saddle’s weight and durability.

-

The Cantle: Located at the rear of the saddle, the cantle offers additional support when the rider is in the “dropped position”. It also prevents the rider from sliding too far back during steep descents.

Planning the Bend

- Discuss the factors to consider when determining the radius of curvature, angle of bend, and location of the bend.

Planning the Bend: A Critical Step in Saddle Customization

When it comes to saddle bending, meticulous planning is paramount. Three crucial factors to consider are:

-

Radius of Curvature: This refers to the degree of curvature applied to the saddle. A smaller radius will create a more rounded saddle, while a larger radius will result in a flatter shape. The ideal radius depends on the rider’s pelvic width and riding style.

-

Angle of Bend: This determines the forward or backward tilt of the saddle. A forward tilt can help mitigate pressure on sensitive areas, while a backward tilt can provide better power transfer. The angle of bend should be customized based on the rider’s body geometry and preferred riding position.

-

Location of the Bend: The bend can be applied to different sections of the saddle. A central bend offers a more balanced feel, while a rearward bend can relieve pressure on the tailbone. Determining the optimal location depends on the rider’s riding style and comfort level.

Considering these factors will ensure that the bent saddle fits the rider like a glove and provides the ultimate comfort and performance.

Choosing the Right Tools for Saddle Bending

Saddle bending is an art that requires a carefully curated set of tools. The right tools will empower you to execute precise bends, ensuring your saddle perfectly complements your unique riding style and body type.

1. Saddle Bending Jig

- The foundation of your saddle bending operation.

- Clamps your saddle securely, providing a stable base for bending.

- Adjustable jaws accommodate various saddle sizes.

2. Heat Gun

- The instrument that softens the saddle material.

- Precise temperature control prevents damage.

- Use a gentle, sweeping motion to evenly distribute heat.

3. Bending Pliers

- Precision tools for gradual bending.

- Choose pliers with a radius and angle appropriate for your desired bend.

- Apply force gradually to avoid excessive deformation.

Securing the Saddle: A Crucial Step in Saddle Bending

Before embarking on the saddle bending process, it’s essential to securely clamp your saddle to the bending jig or vise. This step ensures that the saddle remains stable and firmly in place throughout the bending procedure, preventing any unwanted movement or damage.

To properly clamp the saddle, begin by placing it on the bending jig or vise, ensuring it’s positioned correctly. Align the rails of the saddle with the corresponding grooves on the jig or vise. Once the saddle is in place, tighten the clamps evenly and gradually. Avoid overtightening, as this could damage the saddle rails.

Verify that the saddle is securely held in place by attempting to gently wiggle it. If the saddle moves, adjust the clamps until it’s firmly fixed. This step is crucial because a loose saddle can slip or shift during bending, resulting in an uneven or distorted bend.

Applying Heat: Preparing the Saddle for Bending

Before embarking on the task of bending a saddle, it’s crucial to soften its material to ensure a pliable and moldable base. This is achieved through the judicious application of heat. The heat source, temperature, and duration play pivotal roles in this process.

1. Heat Source:

The choice of heat source depends on the available resources and personal preference. A heat gun is a common choice for its focused and controlled heat distribution. Alternatively, a torch can be employed, but it requires a steady hand and meticulous attention to avoid overheating.

2. Temperature:

The temperature at which the saddle material becomes pliable varies depending on its composition. Leather saddles typically require a temperature between 140-160°F (60-71°C), while synthetic saddles may need slightly higher temperatures. Using a thermometer or temperature probe is advisable to ensure precision.

3. Duration:

The duration of heat application depends on the thickness and material of the saddle. As a general rule, it’s better to apply heat gradually and evenly, allowing the material to absorb the heat thoroughly. Excessive heat can cause damage, so it’s wise to start with a lower temperature and increase it gradually as needed.

By adhering to these guidelines, the saddle will be adequately softened, making it malleable and receptive to the bending process. This step sets the stage for a successful and precise saddle customization.

Bending the Saddle Gradually: A Step-by-Step Guide

As you embark on the transformative process of saddle bending, the moment of truth arrives when you must meticulously shape the saddle to conform to your unique anatomy. This delicate procedure requires patience, precision, and a steady hand.

Choosing the Right Tools: Before commencing, ensure you have the necessary arsenal of tools at your disposal. A saddle bending jig or vise will provide a stable platform for your work. Heat guns, with their adjustable temperature settings, are essential for softening the saddle material. Bending pliers, specifically designed for this task, will enable you to apply controlled force with pinpoint accuracy.

Securing the Saddle: With your tools in place, carefully secure the saddle to the bending jig or vise. Ensure it is firmly held but not so tightly as to impede bending.

Applying Heat: Now, it’s time to gently coax the saddle material into a pliable state. Using your heat gun, apply heat to the targeted area, maintaining a steady temperature and avoiding excessive exposure. As the material softens, you will notice a subtle change in its texture and color.

Bending with Precision: With the saddle sufficiently heated, it is time to carefully bend it to the desired shape. Use bending pliers to apply gentle, consistent force. Avoid abrupt movements or excessive pressure, as this can damage the saddle. Follow the contours of the saddle, gradually bending it to your specifications.

Slow and Steady Wins the Race: Remember, haste makes waste. Bending the saddle is an iterative process. Apply heat in short bursts, allowing the saddle to cool slightly between bends. This gradual approach ensures its integrity and prevents warping.

Cooling and Annealing: Once the saddle has reached its desired shape, it is crucial to allow it to cool slowly. This prevents internal stresses from building up and ensures a stable, durable bend. To further enhance the saddle’s structural integrity, it is recommended to anneal it by heating it to a specific temperature and then allowing it to cool gradually. This process helps to relieve residual stresses and increases the saddle’s longevity.

Shaping and Smoothing: The saddle bending journey is not complete without a touch of refinement. Use files and sandpaper to shape the saddle’s contours, ensuring a smooth and comfortable surface. Polish the saddle to give it a sleek, professional finish.

Cooling and Annealing the Saddle

After bending the saddle to your desired shape, it’s crucial to cool it properly to prevent warping and relieve internal stresses. This process involves two important steps: cooling and annealing.

Cooling

Immediately after bending, let the saddle cool slowly and uniformly. This prevents uneven cooling that can cause the leather to warp or crack. Avoid placing the saddle in direct sunlight or exposing it to a heat source, as this can accelerate cooling and lead to unwanted distortions.

Annealing

Once the saddle has cooled to room temperature, it’s time for annealing. This involves heating the leather again, but at a lower temperature, to relieve the stresses that have built up during bending. Annealing helps to stabilize the shape of the saddle and make it more durable and comfortable to ride on.

To anneal the saddle, use a heat gun set to a low temperature. Move the heat gun evenly over the surface of the saddle, working in small sections at a time. Avoid overheating any one spot, as this can damage the leather.

When the saddle has been heated to a moderate temperature, let it cool slowly and uniformly as before. You may repeat the heating and cooling process several times to achieve optimal results.

Importance of Cooling and Annealing

Proper cooling and annealing are essential for the longevity and performance of your saddle. By following these steps, you can ensure that your saddle maintains its shape, stays comfortable to ride on, and provides years of reliable use.

Shaping and Smoothing the Saddle for Comfort and Aesthetics

Once your saddle is bent to your desired specifications, it’s time to shape and smooth it for a comfortable and aesthetically pleasing finish. This step is crucial for ensuring a saddle that not only fits your body perfectly but also adds to the overall beauty of your bike.

Tools and Techniques

For shaping and smoothing, you’ll need a set of files, sandpapers with varying grits, and polishing pads. Begin by using coarse files to remove any rough edges or sharp points. Gradually move on to finer files and sandpapers to smooth out the surface.

Shaping and Refining

Pay special attention to the contact points where your legs and thighs will come into contact with the saddle. Shape these areas gently to conform to the curves of your body, providing maximum comfort. Use a pencil or felt-tip marker to mark the areas that need more shaping or smoothing.

Smoothing and Polishing

Once the saddle is shaped to your satisfaction, it’s time to achieve a smooth and polished finish. Start with fine-grit sandpaper to remove any imperfections, then switch to polishing pads to give the saddle a gleaming sheen. The extra time and effort spent on smoothing will result in a saddle that feels good on your skin and looks visually appealing.

Tips for a Professional Finish

- Use a soft touch: Avoid applying excessive pressure when filing or sanding, as this can damage the material.

- Be patient: Shaping and smoothing takes time. Don’t rush the process, and focus on creating a smooth and even finish.

- Inspect and adjust: Regularly check your progress with a straightedge or angle gauge to ensure you’re achieving the desired shape and contours.

- Test ride and fine-tune: Once the saddle is shaped and smoothed, take it for a test ride to assess its comfort level. Make any necessary adjustments based on your feedback, and continue refining the saddle until it feels perfect.

Checking and Adjusting the Bend: Ensuring a Perfect Saddle Fit

The final step in saddle bending is checking and adjusting the bend to ensure it perfectly conforms to your unique riding style and body type. Measuring and verifying the saddle bend radius and angle are crucial to achieve optimal comfort and performance on the bike.

Measuring Saddle Bend Radius and Angle

To measure the saddle bend radius, use a saddle bend gauge. Place the gauge on the saddle’s seating surface and adjust it until the gauge’s curve matches the saddle’s curvature. Read the measurement displayed on the gauge, which indicates the saddle bend radius.

Next, to measure the saddle bend angle, use an angle meter. Position the angle meter on the saddle so that its base is parallel to the saddle rails. Adjust the angle meter until its arm aligns with the saddle’s bending point. The angle displayed on the meter represents the saddle bend angle.

Verifying the Bend and Making Adjustments

After measuring, compare the saddle bend radius and angle to your desired specifications. If adjustments are necessary, make them gradually using bending pliers or a jig. Remember to reheat the saddle before bending to avoid damage.

Ride Testing and Refinement

Once the saddle is bent, take it for a test ride to assess its comfort and performance. Pay attention to any pressure points, discomfort, or instability. If needed, make further adjustments based on your observations to fine-tune the saddle’s fit.

Checking and adjusting the saddle bend is a crucial step in customizing your saddle for a perfect fit. By precisely measuring and verifying the bend radius and angle, you can ensure a saddle that provides maximum comfort, efficiency, and enjoyment on your cycling adventures. Remember to consult a professional bike fitter or experienced cyclist if you encounter any difficulties or have any specific fit concerns.