Percent recovery evaluates the efficiency of processes by comparing the initial (starting) and final (ending) amounts of a substance. Calculated using the formula (Final Amount / Initial Amount) x 100%, percent recovery provides insights into the effectiveness of reactions, extraction procedures, and manufacturing processes. It helps optimize processes by identifying inefficiencies and potential areas for improvement. While experimental conditions and accuracy can influence results, percent recovery remains an important metric for assessing efficiency, comparing methods, and improving outcomes in various fields like chemistry, engineering, and manufacturing.

Unveiling the Secrets of Percent Recovery

In the realm of science, chemistry, and engineering, the concept of percent recovery plays a pivotal role in evaluating the efficiency of processes and reactions. It’s a numerical expression that quantifies the amount of a substance or product obtained relative to its anticipated or theoretical yield.

Percent recovery provides a crucial metric for assessing the effectiveness of experimental procedures, optimizing industrial processes, and comparing different methodologies. It helps scientists and engineers determine how efficiently a reaction or process converts starting materials into desired products, identifying areas for improvement and maximizing productivity.

Understanding Key Concepts: Initial and Final Amounts in Percent Recovery

To comprehend percent recovery, it’s essential to understand the fundamental concepts of initial amount and final amount.

The initial amount refers to the starting quantity of a substance or product at the beginning of a process or reaction. This amount represents the total quantity available before any transformations or changes occur. For instance, if you start with 100 grams of a chemical compound, the initial amount is 100 grams.

The final amount represents the ending quantity of the substance or product at the conclusion of the process or reaction. This amount is the result of any transformations, reactions, or losses that have taken place. For example, if you end up with 80 grams of the compound after the process, the final amount is 80 grams.

Understanding these key concepts is crucial because percent recovery is a direct comparison between the final amount and the initial amount. It provides insights into the efficiency of a process by quantifying the amount of substance or product that is successfully recovered or obtained.

Formula for Percent Recovery: Assessing Process Efficiency

Understanding percent recovery is crucial in evaluating how effectively processes and reactions perform. The formula for calculating percent recovery provides a quantitative measure of this efficiency.

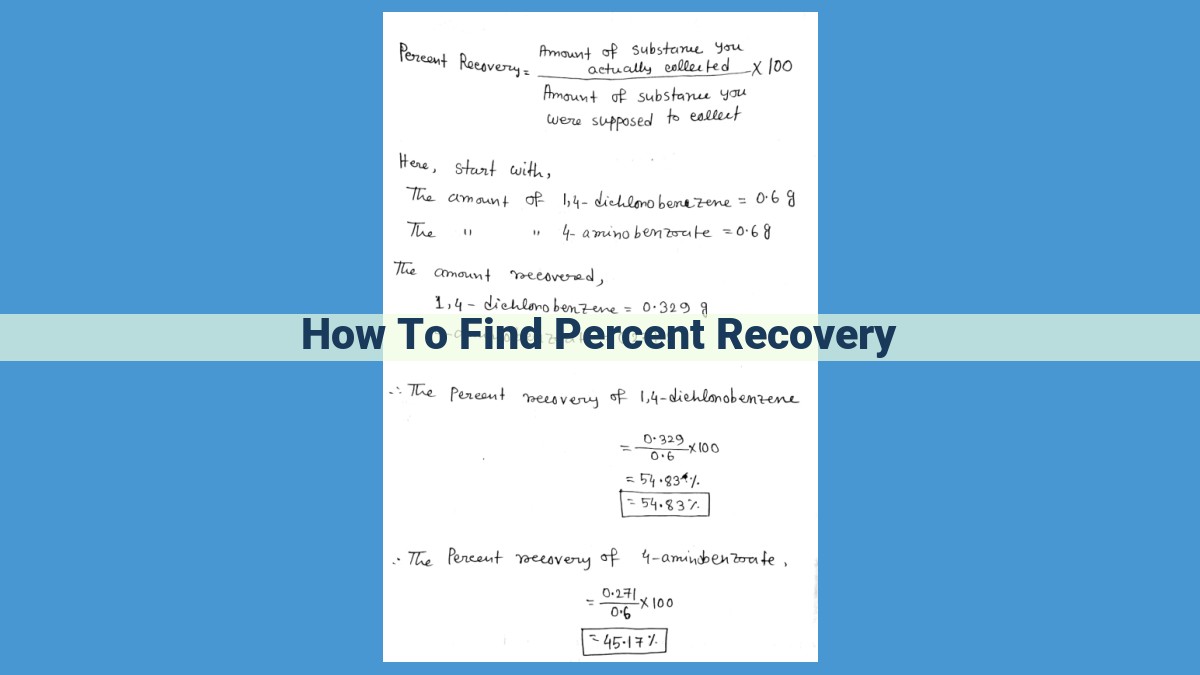

The percent recovery formula is:

Percent Recovery = (Final Amount / Initial Amount) x 100%

Where:

- Final Amount: The quantity of product obtained at the end of the process or reaction.

- Initial Amount: The original quantity of reactant present at the start of the process or reaction.

Breaking Down the Formula

The numerator, Final Amount, represents the actual yield of the process. The denominator, Initial Amount, represents the theoretical maximum yield that could have been obtained. The ratio of these two values provides an indicator of how close the actual yield is to the ideal yield.

Significance of Experimental Conditions

Experimental conditions can significantly impact percent recovery. Factors such as temperature, pressure, and reaction time influence the outcome of the process. It’s essential to note the specific conditions under which the percent recovery is calculated to ensure accurate comparisons.

Potential Sources of Error

- Measurement errors: Inaccurate measurements of initial or final amounts can lead to incorrect percent recovery values.

- Incomplete reactions: Reactions that do not go to completion result in lower percent recoveries.

- Side reactions: Unwanted reactions can compete with the desired reaction, reducing the yield and percent recovery.

By carefully controlling experimental conditions and accounting for potential errors, the percent recovery formula provides a reliable assessment of process efficiency.

Calculating Percent Recovery: A Step-by-Step Guide

Percent recovery, a crucial measure in assessing the efficiency of processes and reactions, provides valuable insights into the effectiveness of your experiments. Understanding how to calculate percent recovery is essential for optimizing your techniques and evaluating their performance.

Step 1: Define the Initial and Final Amounts

The initial amount refers to the starting quantity of the substance you’re investigating, while the final amount is the amount you have after the process or reaction has taken place. Determining these values accurately is essential for a precise percent recovery calculation.

Step 2: Apply the Formula

The formula for percent recovery is:

Percent Recovery = (Final Amount / Initial Amount) x 100%

By dividing the final amount by the initial amount and multiplying the result by 100, you obtain a percentage that represents the efficiency of your process.

Step 3: Significance of Experimental Conditions

The conditions under which your experiment is conducted can significantly impact the percent recovery. Factors like temperature, pressure, and reaction time can influence the efficiency of a process. It’s essential to standardize these conditions to ensure reproducible results.

Step 4: Potential Sources of Error

Errors in measurement or experimental techniques can affect the accuracy of your percent recovery calculation. Using calibrated equipment, following proper procedures, and minimizing human error are crucial to obtain reliable results.

Applications of Percent Recovery

Percent recovery finds widespread applications across various fields, proving invaluable in evaluating the efficiency of processes and reactions.

In Chemistry

Percent recovery is a crucial parameter in chemical synthesis, helping researchers assess the yield and efficiency of their reactions. By comparing the actual product obtained to the theoretical yield, chemists can fine-tune their procedures, optimize reaction conditions, and minimize waste.

In Engineering

Engineers rely on percent recovery to evaluate the performance of filtration and purification systems. By determining the amount of solute recovered after treatment, they can assess the effectiveness of their filtration media and optimize system design to maximize recovery and minimize environmental impact.

In Manufacturing

In manufacturing, percent recovery plays a vital role in process optimization and quality control. For instance, in pharmaceutical manufacturing, it helps determine the efficiency of extraction and purification processes, ensuring the production of high-quality products with minimal loss of active ingredients.

In summary, percent recovery is a valuable tool across diverse fields, providing insights into the efficiency and effectiveness of processes and reactions. By evaluating the percentage of starting material recovered, researchers, engineers, and manufacturers can optimize their procedures, improve product yield, and minimize waste.

The Importance of Percent Recovery in Optimizing Processes

In a world where efficiency reigns supreme, percent recovery plays a pivotal role in the optimization of processes across various industries. It serves as an invaluable tool for assessing the effectiveness of reactions, evaluating the performance of methods, and identifying areas for improvement.

By comparing percent recovery values, scientists, engineers, and manufacturers can determine the most efficient processes, optimize resource utilization, and minimize waste. It allows them to pinpoint bottlenecks and inefficiencies, enabling them to make informed decisions to enhance productivity and profitability.

Moreover, percent recovery provides a benchmark for evaluating different methods or techniques. It allows researchers to compare the effectiveness of alternative approaches and identify the one that yields the highest recovery. This knowledge can inform decision-making when selecting the most suitable method for a specific purpose.

In summary, percent recovery is a cornerstone of process optimization and efficiency evaluation. By understanding and utilizing this metric, industries can maximize their output, minimize their environmental impact, and gain a competitive edge.

Limitations of Percent Recovery

- Discuss potential inaccuracies and limitations due to experimental errors or assumptions.

- Emphasize the importance of accurate measurements.

Limitations of Percent Recovery

Understanding the limitations of percent recovery is crucial for accurate interpretation of results and informed decision-making. It is important to note that percent recovery may not always provide a completely accurate representation of the efficiency of a process or reaction.

-

Experimental Errors: Experimental conditions can significantly affect results. Factors such as temperature, time, and instrumentation can introduce variability, leading to inaccuracies. For example, if the temperature is not carefully controlled, it could alter the reaction rate, affecting the yield and ultimately the percent recovery.

-

Assumptions: Percent recovery is based on assumptions about the starting and ending amounts. These assumptions often involve assuming complete reactions or perfect separation. However, in reality, reactions may not proceed entirely as expected, and there may be losses during the separation process. These assumptions can introduce errors and affect the reliability of the results.

Accurate measurements are paramount to minimizing these limitations. Proper calibration of instruments, careful sample preparation, and attention to experimental conditions are essential for obtaining reliable percent recovery values.

By recognizing the limitations of percent recovery, scientists and engineers can interpret results more accurately and make more informed decisions about process optimization and efficiency evaluations.

Related Concepts: Recovery, Yield, and Efficiency

Beyond percent recovery, understanding related concepts like recovery, yield, and efficiency is crucial for assessing the outcomes of processes and reactions. These concepts are closely intertwined and provide a comprehensive picture of the performance and effectiveness of a given method or system.

Recovery refers to the amount of a substance or product that is obtained after a process or reaction. It is expressed as a percentage of the initial amount or starting quantity. Percent recovery, as discussed earlier, is a measure of how efficient a process is in recovering the desired substance.

Yield is another important concept related to percent recovery. Yield represents the amount of product obtained compared to the theoretical maximum that could be produced under ideal conditions. It is also expressed as a percentage and provides insights into how effective a process is in converting reactants into the desired product.

Efficiency encompasses both recovery and yield. It evaluates how effectively a process utilizes resources, minimizes waste, and maximizes the production of the desired substance. A highly efficient process will have a high percent recovery and a **high yield.

Understanding these related concepts allows us to:

- Compare different methods or processes: By assessing percent recovery and yield, we can determine which approach is more effective and efficient in achieving the desired outcome.

- Optimize processes: Identifying potential areas of improvement in terms of recovery, yield, and efficiency can lead to the development of more efficient and cost-effective processes.

- Evaluate overall performance: Combining percent recovery, yield, and efficiency provides a comprehensive evaluation of the effectiveness and sustainability of processes and reactions.